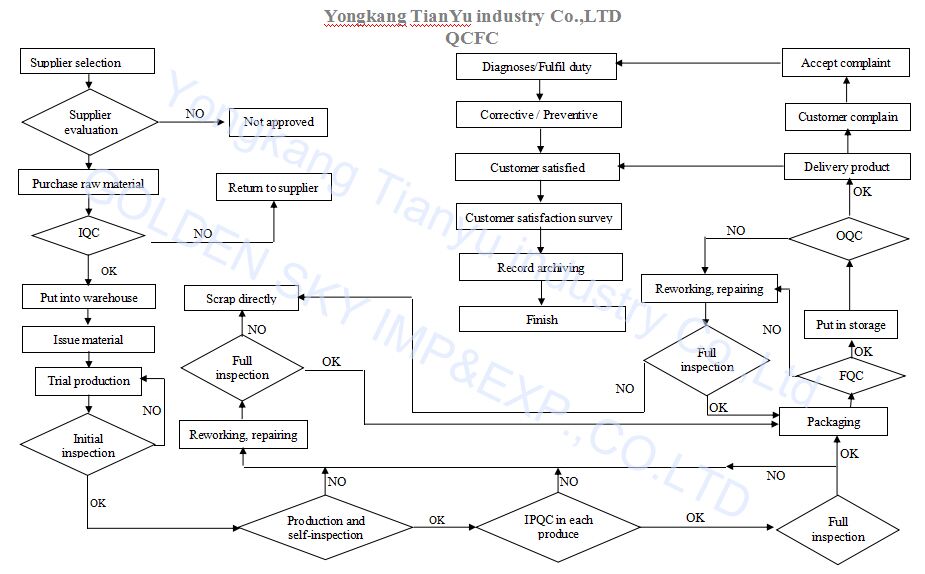

The specific process of product quality control is as follows:

First of all, the company will look for a lot of high-quality suppliers for each kind of raw materials, accessories, by the company's technical department, quality department, procurement department in accordance with the company's evaluation criteria for suppliers. Finally, 5-6 qualified suppliers are selected from these suppliers to enter the company supplier system.

When purchasing department needs to purchase raw materials or accessories, must enter the company supplier system to select suppliers; Samples of materials or accessories needed by the company are first supplied by the selected supplier, and tested by the technical department of the company, and then passed to the quality control department of the company for inspection. The samples shall be saved by IQC after the inspection. Finally, the purchasing department will be informed to purchase the samples.

When the purchased raw materials or accessories arrive at our company, the IQC first according to the company established acceptance standards, the retention of qualified standards. Carry out sampling or full inspection acceptance in conjunction with international sampling plan.

When the complete raw materials or accessories into the production line, each production point will first produce, the first product trial production through full-time technical personnel, quality personnel test, qualified. After locking the equipment production parameters of the production point, the production point can be put into the formal production in large quantities; In the production process of each production site, in addition to the production workers own inspection, there are full-time IPQC personnel regular inspection.

When all the spare parts are finished, and pass the full-time quality staff inspection and qualified, can enter the assembly workshop for assembly and packaging; After assembly and packaging, the FQC staff will sample the products according to the order requirements of each customer and the inspection standard of the products according to the international sampling plan. Only qualified products can enter the finished product warehouse.

Received delivery notice to the customer, according to the quality standard and the request of the guests of the company, the batch of products for shipment acceptance by professional OQC personnel; only after acceptance can accept customers or clients to the third party inspection company for inspection, the batch of product acceptance; only fully qualified products to delivery to the customer to enter the market.

If the quality of products and services received customer complaints, the company customer service department technical department, quality department and other professional personnel to the guest for a detailed analysis, judgment, to review the occurrence causes and prevention of quality problems, corrective measures, and to prevent the implementation of corrective action is valid. The full-time training and examination of the original quality problem caused by the staff to operate the personnel, only master the prevention and corrective measures before they can enter the production line for production; corresponding to the production equipment, testing equipment production, testing parameters according to the preventive, corrective measures required to re adjust. There have been more than the corresponding quality causes and prevention the problem, corrective measures will be archived in the form of a document, so that later in the production process, key control.

Zhejiang Tianyu Industry Co.,Ltd QCFC